From ltaly to serve the world

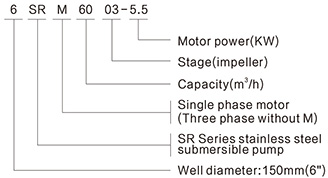

6SR60

TECHNICAL DATA:

-Pump/Motor

Qmax: 75(m³/h)

Adopted the NEMA standard

lnsulation class: F

Protection grade: IP 68

Maximum diameter: φ150mm

Highest temperature of liquid: 35℃

Options of different materials are available.

| Type |

Motor power |

Capacity and head | Length | |||||||||||||||

|

single phase 220-240V~ Hz50 |

Three phase 380-415V~ Hz50 |

|||||||||||||||||

| L/ min | 0 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 | |||||

| KW | HP | m³/h | 0 | 6 | 12 | 18 | 24 | 30 | 36 | 42 | 48 | 54 | 60 | 66 | 72 | mm | ||

| 6SRM60 03-5.5 | 6SR60 03-5.5 | 5.5 | 7.5 |

Head (m) |

41 | 40 | 39 | 37 | 35 | 33 | 31 | 28 | 26 | 24 | 22 | 19 | 17 | 1419 |

| — | 6SR60 04-7.5 | 7.5 | 10 | 54 | 53 | 52 | 50 | 47 | 44 | 41 | 38 | 34 | 32 | 29 | 26 | 22 | 1576 | |

| — | 6SR60 05-11 | 11 | 15 | 68 | 67 | 65 | 62 | 59 | 55 | 51 | 47 | 43 | 40 | 36 | 32 | 28 | 1782 | |

| — | 6SR60 06-13 | 13 | 17.5 | 81 | 80 | 78 | 75 | 70 | 66 | 61 | 57 | 51 | 48 | 43 | 39 | 33 | 1938 | |

| — | 6SR60 07-15 | 15 | 20 | 95 | 93 | 91 | 87 | 82 | 76 | 71 | 66 | 60 | 55 | 50 | 45 | 39 | 2166 | |

| — | 6SR60 08-18.5 | 18.5 | 25 | 108 | 107 | 104 | 100 | 94 | 87 | 82 | 75 | 69 | 63 | 58 | 51 | 45 | 2322 | |

| — | 6SR60 09-18.5 | 18.5 | 25 | 122 | 120 | 117 | 112 | 105 | 98 | 92 | 85 | 77 | 71 | 65 | 58 | 50 | 2429 | |

| — | 6SR60 10-22 | 22 | 30 | 135 | 134 | 130 | 125 | 117 | 109 | 102 | 94 | 86 | 79 | 72 | 64 | 56 | 2615 | |

| — | 6SR60 11-26 | 26 | 35 | 149 | 147 | 143 | 138 | 129 | 120 | 112 | 104 | 94 | 87 | 79 | 71 | 61 | 2801 | |

| — | 6SR60 13-30 | 30 | 40 | 176 | 174 | 169 | 163 | 152 | 142 | 133 | 123 | 111 | 103 | 94 | 84 | 72 | 2987 | |

| — | 6SR60 14-30 | 30 | 40 | 189 | 187 | 182 | 175 | 164 | 153 | 143 | 132 | 120 | 111 | 101 | 90 | 78 | 3200 | |

rpm:2850 Outlet:G3"~G4"

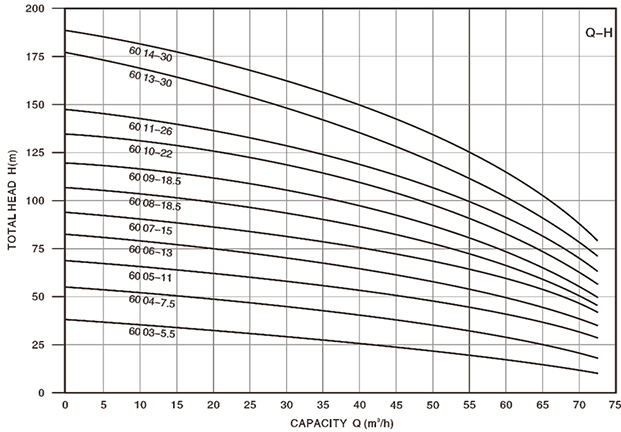

| N0. | Description | N0. | Description | N0. | Description | N0. | Description |

|---|---|---|---|---|---|---|---|

| 1 |

Clamping spring |

14 |

O-ring |

27 |

Suction support |

40 |

Bearing bush |

| 2 |

End cover |

15 |

Oil chamber |

28 |

Strainer |

41 |

Screw |

| 3 |

Rubber cup |

16 | O-ring | 29 |

Screw |

42 |

Screw |

| 4 |

Motor body |

17 |

Screw |

30 |

Screw |

43 | Diffuser |

| 5 |

Screw |

18 |

Sand proof sheath |

31 |

Coupling |

44 |

Guide bush |

| 6 |

Washer |

19 |

Washer |

32 |

Bearing bush |

45 |

Valve seat |

| 7 |

Bearing seat |

20 |

Sand proof cap |

33 |

Intermediate support |

46 |

Check valve |

| 8 |

Stator |

21 |

Screw |

34 |

Guide bush |

47 | Screw |

| 9 |

Ball bearing |

22 |

Oil chamber cover |

35 |

Shaft |

48 |

Holder pipe |

| 10 |

Rotor |

23 |

Cable |

36 |

Shaft ring |

49 |

Cable cover |

| 11 |

Ball bearing |

24 |

Stud |

37 |

Diffuser cover |

50 |

Pump bod |

| 12 |

Gasket |

25 |

washer |

38 |

Impeller |

51 |

Outlet |

| 13 |

Thrust bearing |

26 |

Nut |

39 |

Diffuser |

52 |

Control box |